Soosung Valve Ind. Co., Ltd. that achieves best quality and customer satisfaction

Cryogenic Process

STEP 1

Jig assembled to the valve

STEP 2

In a tank of LN2 Charge

STEP 3

Cryogenic stabillzation

STEP 4

Cryogenic test Progress

STEP 5

Cryogenic test Progress

STEP 6

Cryogenic test complete

STEP 7

Return to room temperature test

STEP 8

Packing after nitrogen gas plush packing

Test Facilities for Cryogenic Service

Safety Guard

Gas Booster System

Cryogenic Test

Test Facilities for Cryogenic Service

- Assemble the valve that completed cold emulsion treatment and install it to the flanges for enabling the test. Input and output port shall be made on the flanges in advance.

- Submerge the valves installed to the flanges into the vessel of liquified Nitrogen Gas with the vertical arrangement for cryogenic status.

- Allow enough time for the submerged valves until the temperature of valve reaches to -196°C.

- Under the cryogenic status, inject the nitrogen or helium gas into the flanges at the applicalbe pressure.

- Measure the leaked volume of nitrogen or helium gas from the seat area for the duration of one minute. Measured leak volume shall be decided for acceptance or non-acceptance in accordance with the criteria to BS 6364, that is, 200mm/sXDN(12ccXDN).

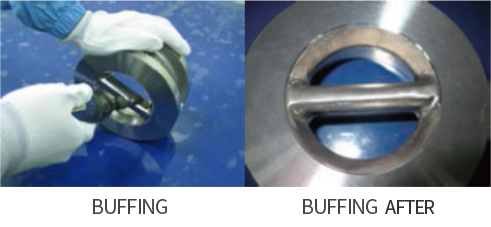

Cleaning Process

STEP 1

STEP 2

STEP 3

STEP 4

STEP 5

STEP 6

Cleaning Room Facility